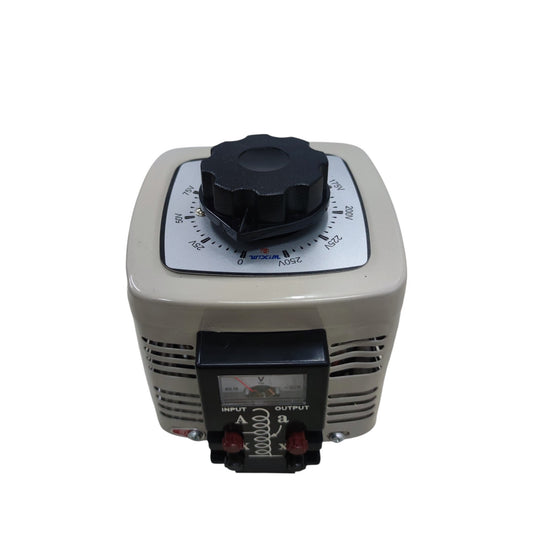

Variac Single Phase or 3 Phase: A variac (variable autotransformer) allows for smooth and continuous adjustment of AC voltage. They come in both single-phase and three-phase configurations to suit different electrical systems and applications.

Single-Phase Variac:

-

Purpose: Designed for single-phase AC power systems, commonly found in residential, office, and light commercial settings.

-

Applications:

-

Laboratories and R&D: Precise voltage control for experiments, testing electronic components, and calibrating equipment.

-

Motor Speed Control: Used for controlling the speed of single-phase AC motors, especially those with low starting torque (e.g., fans).

-

Lighting Dimming: Adjusting the brightness of incandescent lamp circuits in theatrical lighting, studios, or industrial settings.

-

Vintage Equipment Restoration: Gradually powering up old electronic equipment (e.g., tube amplifiers) to prevent damage from sudden full voltage.

-

Heater Control: Regulating the temperature of resistive heating elements in ovens or industrial processes.

-

Voltage Compensation: Boosting or bucking voltage to compensate for line voltage fluctuations or drops over long cables.

Three-Phase Variac:

-

Purpose: Designed for three-phase AC power systems, typically found in industrial, commercial, and high-power environments where larger equipment and machinery are used.

-

Applications:

-

Industrial Motor Speed Control: Adjusting the speed of three-phase industrial motors (e.g., for pumps, conveyors) without the need for complex electronic drives.

-

High-Capacity Heater Regulation: Precise temperature control for large industrial heaters.

-

Large Lighting Systems: Dimming or controlling the brightness of extensive industrial or architectural lighting installations.

-

Industrial Equipment Testing: Providing controlled, balanced voltage for testing heavy-duty machinery and systems under various voltage conditions.

-

Power Stabilization: Ensuring consistent voltage supply for sensitive industrial electronics.

-

Research Labs and Manufacturing: Essential for environments requiring consistent power delivery and high-efficiency operation for demanding applications.

Key Differences:

-

Number of Windings: A single-phase variac has a single winding, while a three-phase variac has three interconnected windings, one for each phase.

-

Power Capacity: Three-phase variacs are designed to handle significantly higher power loads than single-phase variacs.

-

Complexity: Three-phase systems and their variacs are more complex, involving three separate voltage waveforms spaced 120° apart to provide continuous and balanced power flow.

-

Cost and Size: Three-phase variacs are generally larger, heavier, and more expensive due to their increased complexity and power handling capabilities.

Both types provide continuous voltage adjustment by means of a movable carbon brush or wiper that slides along the winding, effectively changing the turns ratio and thus the output voltage.